In recent years, "infrastructure mania" and "mega-projects" have gradually become uniquely Chinese "calling cards." When people think of mega-projects, China immediately comes to mind—examples include the Hong Kong-Zhuhai-Macao Bridge and Beijing Daxing International Airport. These mega-projects are important demonstrations of China's technological strength and comprehensive national power, showcasing Chinese precision, speed, height, and scale. They repeatedly create miracles, filling the nation with pride and astonishing the world. When it comes to such mega-projects, the "China Zun" from Beijing naturally ranks among the most prominent.

Beijing's Tallest Building—China Zun

China Zun (official name: CITIC Tower) gets its nickname from its striking resemblance to the ancient ritual vessel "Zun." Construction officially began on July 29, 2013. The underground structure was fully topped out on December 10, 2014. The structural height surpassed 100 meters in September 2015, 200 meters in March 2016, reached 300 meters on August 18 of the same year, and exceeded 400 meters on November 9. In June 2017, it passed the 500-meter mark. On August 18, the steel structure of the tower crown was hoisted into place, and concrete pouring for the 106th floor of the outer frame was completed, successfully topping out Beijing’s tallest building. The project was fully completed in October 2018, with phased delivery beginning on December 28 of the same year. On November 22, 2019, China Zun successfully passed final acceptance inspection.

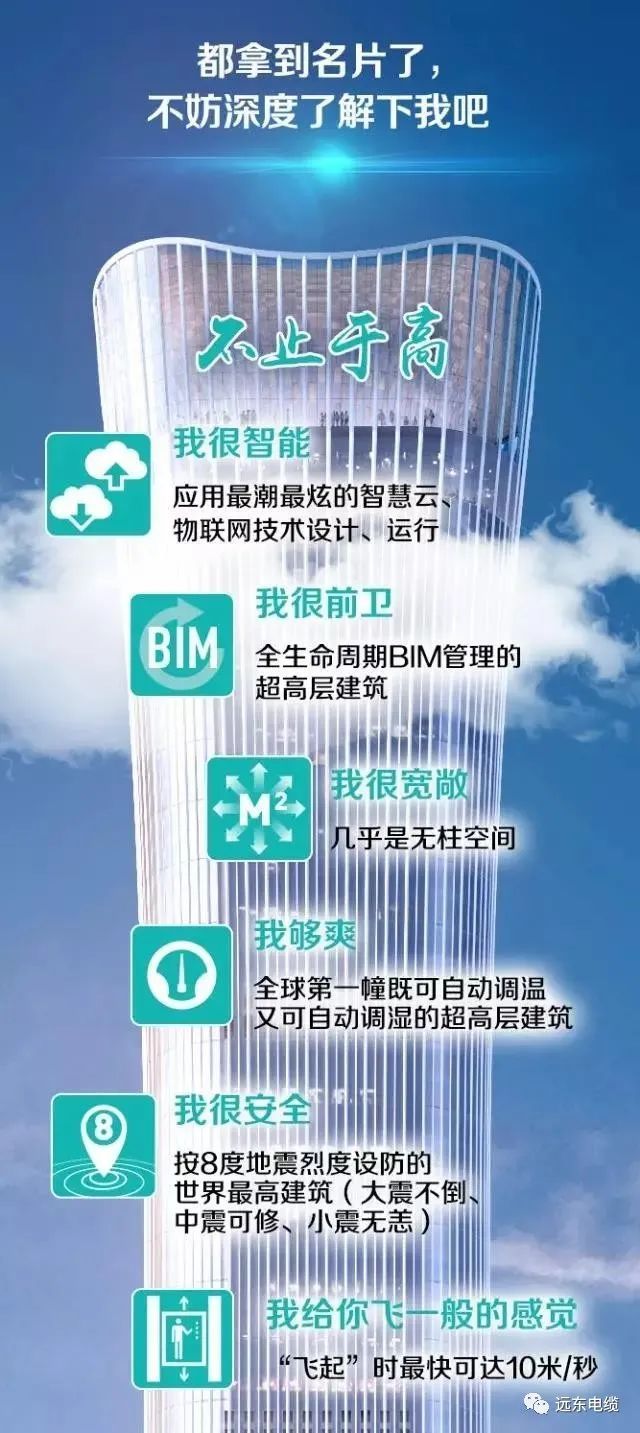

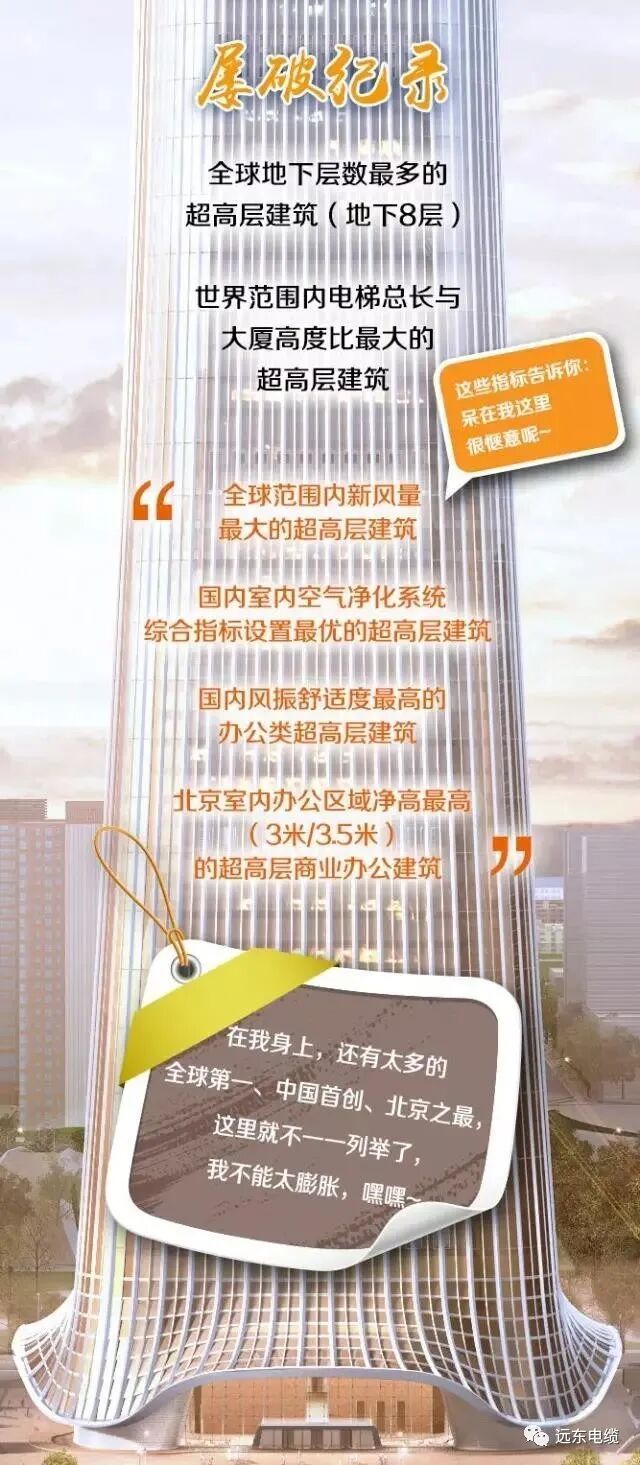

Covering a floor area of 437,000 square meters and standing 528 meters tall, with 108 floors above ground and 7 below, China Zun integrates Grade A office space, conference facilities, commercial areas, observation decks, and various supporting services, capable of accommodating 12,000 office workers. From land acquisition and design to construction and completion, the entire project took eight years. Today, it ranks ninth globally and fifth in China by height, serving as the most significant structure on the central axis of Beijing’s CBD, redefining the capital’s skyline. Meanwhile, the project has set eight world records and 15 national records.

High Technical Requirements, Challenging Construction

China Zun was jointly implemented by the main contractor consortium of CSCEC Corporation Limited and CSCEC Third Engineering Bureau, along with mechanical and electrical contractor CSCEC Installation. From the outset, the project team established the ECPO innovative management model, proactively considering how to maximize energy efficiency during construction and applying nearly stringent standards when selecting equipment and material suppliers. In short, any supplier accepted by China Zun is almost certainly recognized as a top-tier leader in their respective field. It is precisely due to the participation and contributions of these capable enterprises that China Zun stands so proudly today.

As is well known, super high-rise buildings have numerous electrical devices, large power loads, multiple power sources, vast floor areas, and dense populations—all of which pose significant challenges to electrical safety and cost-efficiency. Therefore, for China Zun, ensuring proper cable installation and reliable power supply became a critical hurdle to overcome.

Especially given China Zun’s unique circumstances—standing 528 meters tall and requiring twelve cables to be safely arranged in a continuous vertical run within a narrow 450mm-wide electrical shaft—the difficulty of vertical cable hoisting was significantly increased. Technical considerations such as cable positioning, routing, and auxiliary lifting equipment arrangements had to be carefully planned and monitored in advance to ensure installation requirements were fully met.

Dedicated R&D, Superior Product Performance

Far East Cable Co., Ltd., with 36 years of industry experience, took on this challenging task, providing intelligent building cables for super high-rise hoisting and system design support for China Zun. They exclusively designed, developed, and manufactured the world’s longest special 10KV high-voltage suspended cable—820 meters long—providing continuous power supply to the building. This marked the second time this cable product was used after its initial deployment at the Shanghai World Financial Center, undoubtedly a strong affirmation of Far East Cable’s technical capabilities and innovation.

As early as 2008, Far East Cable became the first domestic supplier to independently develop and supply hoisting cables for super high-rise buildings, providing 10KV hoisting cables for the Shanghai World Financial Center. The longest single cable was 708 meters, weighing 14 tons, hoisted from 131 to over 400 meters. The installation, spanning underground horizontal sections, vertical runs, and upper-level horizontal sections, was a first in China’s building hoisting history at the time.

Shanghai World Financial Center

Despite its extensive prior experience and the successful precedent of the Shanghai World Financial Center, the company approached the China Zun project with utmost seriousness. As the core power source of the entire building, the special 10KV high-voltage suspended cable is crucial—akin to the "main arterial blood vessel" of China Zun. Due to its unique operating environment, the cable must support its own weight regardless of length or weight, and excessive thickness would compromise other performance aspects. Additionally, as a landmark building, higher requirements for environmental friendliness and intelligence posed severe challenges to Far East Cable.

Therefore, starting in 2012, Far East Cable began tracking the China Zun project, conducting multiple discussions with the Beijing Institute of Architectural Design. Based on a thorough understanding of cable laying requirements and technical specifications, they began meticulous preparations for product and system design solutions. In 2016, as construction of China Zun progressed steadily, the Far East team began designing the construction plan. To obtain first-hand data, they visited the construction site multiple times for on-site inspections, ultimately designing a custom special 10KV high-voltage suspended cable tailored specifically to the building’s unique shaft structure—a true "bespoke" solution.

Features of the special 10KV high-voltage suspended cable:

Possesses safety and environmental characteristics such as low smoke, zero halogen, flame retardancy, and fire resistance, meeting fire system power supply requirements and ensuring reliable power delivery in high-rise buildings.

Capable of supporting its own weight regardless of length or weight, effectively solving the problem of ordinary cables being damaged by their own weight during long vertical installations.

Through further technological upgrades, it meets all functional design requirements while offering advantages such as time-saving, labor-saving installation, short construction periods, and minimal space usage.

Offers additional benefits including lower overall investment costs, low maintenance rates, long durability, and excellent stability.

Saves non-ferrous metals, making it more environmentally friendly and intelligent.

On-site ceremony for hoisting the world’s longest special 10KV high-voltage suspended cable

Innovation Solves Technical Challenges

In March 2018, the first batch of special 10KV high-voltage suspended cables dedicated for the China Zun project arrived in Beijing and smoothly entered the site, marking the start of the core power cable installation phase. To ensure smooth cable laying, Far East Cable immediately assembled its R&D and technical service teams, rushing to the construction site immediately after cable delivery to provide professional technical training for the engineering and hoisting teams. Training covered cable protection measures, designated laying positions for each cable, hoisting plans, and key installation precautions.

Far East team conducting hoisting cable laying training

During cable installation, to achieve a more compact structure, the Far East team innovatively designed a dual-cable lifting device for the building’s unique shaft structure. This tool allows two cables to be hoisted simultaneously, effectively solving the issue of conductor damage due to self-weight in long vertical runs. This was another innovative practice by the Far East team in lifting equipment, a first-of-its-kind globally.

From the initial cable laying in March 2018 to the successful installation of the 820-meter-long world’s longest special 10KV high-voltage suspended cable in August, the six-month hoisting operation saw Far East Cable install a total of 24 suspended cables for the China Zun project, totaling 15,132 meters in length and weighing 136.38 tons. This achievement set multiple world firsts and records. This success was made possible by the dedication and efforts of the Far East team, who provided full-process tracking from the moment the cables arrived on site, using innovative technology to overcome technical challenges in super high-rise power systems and ensuring safe, orderly cable installation—marking a new breakthrough in vertical high-voltage cable laying technology for super high-rise buildings.

Wang Chuanbin (second from left), Chief Expert of Far East Cable Industry, providing on-site guidance

The application of Far East Cable’s independently developed hoisting cables for super high-rise buildings in projects like China Zun has greatly improved power supply quality at the receiving ends of such buildings, leading a significant transformation in power supply methods for super high-rises through outstanding performance. Going forward, Far East Cable will further leverage its industrial advantages, focusing on developing and servicing high-end products for green building power distribution systems. Relying on strong R&D and manufacturing capabilities, combined with market and customer needs, the company aims to lead in the development of green buildings and smart cities with smarter products and services, securing greater success in the future.